This 1955-67 Volkswagen bus 3.5 flipped dropped spindle photo shoot is for entertainment purposes only.

This is intended for entertainment reference purposes only! We at Wagenswest do not suggest or recommend using this as a guide, or instructions, or a "how to drop a spindle". Wagenswest will not be held responsible for damages or injuries, that an idiot may incur by using this photo shoot, to modify his or her personal or customers spindles.

#1 - A stock 1955-67 spindle.

#2 - The pinch bolt that needs to be removed, before you press the king pin out.

#3 - Stock spindle in the press.

#4 - Stock spindle in the press. #5 - Stock spindle in the press.

#6 - Stock spindle in the press.

#7 - Stock spindle with the top kingpin pressed out.

#8 - Stock spindle coming apart.

#9 - Gusset spot.

#10 - ¼ by 1 by 1 ¾ gusset .

#11 - Bamming the gusset.

#12- Weld the gusset on.

#13 -Hot stuff.

#14 - Getting ready to clearance, for putting the bottom king pin in the top bush, upside down.

#15 - Using a Bosch yellow jacket to clearance the spindle.

#16 - Using a Bosch yellow jacket to clearance the spindle.

#17 – Clearance is just enough.

#18 – Clearance for the bottom link pin bolt.

#19 – Buff the shafts or have them machined, don’t just put them in if they are bad. You know who you are.

#20 – A stock spindle.

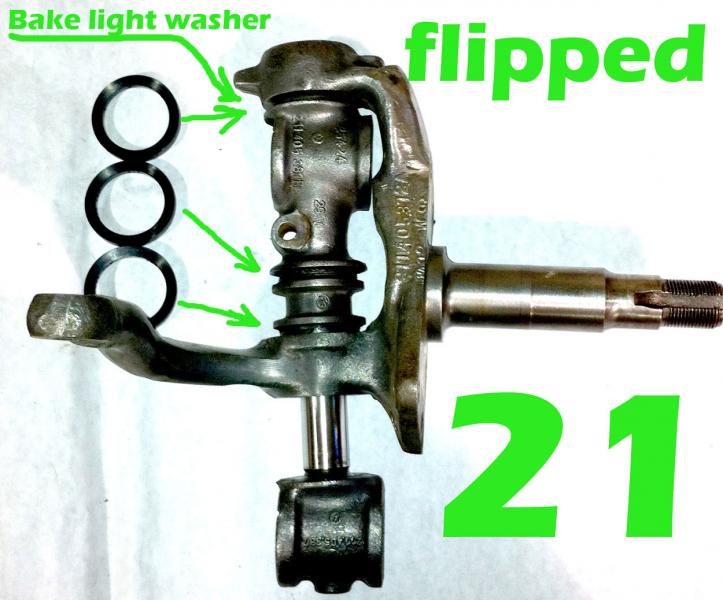

#21 – A flipped spindle configuration.

#22 – Greasing the seals, to get them around the kingpin spacer.

#23 – little screw driver, works good.

#24 – Simple king pin alignment.

#25 - Simple king pin alignment.

#26 – Pressing the king pin together.

#27 – A 3.5 inch flipped dropped spindle.

#28 – Reverse tapering for upside down, post 1968 tie rod ends.

#29 - Simple hand tools.